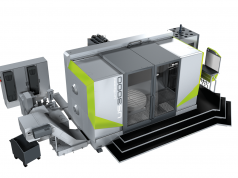

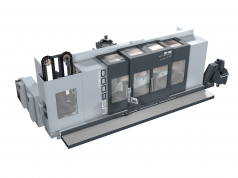

Heckert HEC 800 X5

5-axis machining center

The successful and well proven machines from the Athletic range have been combined with a compact and robust rotary tilting table to provide a highly productive full 5-axis machining center. The powerful and flexible NC control systems fitted to these machines are equally suited to 5-sided, 3+2 axis and full 5-axis contouring. With the options available for tool handling, coolant and in-process measuring, a perfect solution can be tailored to meet any requirement.

With the table swivelling axis A and rotary axis B, surfaces and holes may be machined at any angular position.

The ability to machine 5 sides of a component at a single set-up often simplifies the machining process and can lead to reduced production times and unit costs.

Key benefits:

– Integration process turning through option „MT“

– Optimum cutting conditions and excellent long-term accuracy (high quality horizontal spindle with quadruple bearings)

– Very high accuracy in all linear and rotary axes

– Guaranteed machining accuracy to class IT 5

– Reduced idle times (optimised tool change cycles)

– Optimal tool handling (chain or tower magazine for 40 to 450 tools)

– Large tool dimensions (Bridge tool diameter to 500 mm, tool length up 800 mm)

– Optimal chip flow

– High processing reliability for automised processing

– Maximum precision through temperature control and temperature compensation

Axis Configuration

Technical Data

Please choose the Measuring Unit

| Clamping surface / perforated plate DIN 55201 | mm | 800 x 800 (1,000 x 800) |

| Max. load | kg | 1,200 |

| Max. workpiece-interference diameter | mm | 1,400 |

| Max. workpiece and clamping fixture height | mm | 1,000 |

| Number of changeable pallets | 2 |

| Linear travel X | mm | 1,450 |

| Vertical travel Y | mm | 1,100 (1,300) |

| Traverse travel Z‘ | mm | 1,300 |

| Rotation range B‘-axis | degree | 0 … 360 |

| Swivel range A‘-axis | degree | + 45 … – 91 (- 180) |

| Max. feed range, stepless | mm/min | 1 … 65,000 |

| Rapid traverse rate | m/min | 65 |

| Max. speed B‘-axis | rpm | 60 (500 at MT) |

| Max. speed A‘-axis | rpm | 15 |

| Max. acceleration X / Y / Z | m/s2 | 7 / 7 / 4 |

| Max. feed force X / Y / Z 60% c.d.f. | kN | 20 / 18 / 20 |

| Gear spindle | . | |

| Tool holder | HSK-A 100 (SK 50) | |

| Drive power 25% c.d.f. | kW | 55 (50 / 50 / 83) |

| Torque 25% c.d.f. | Nm | 1,500 (958 / 958 / 1,500) |

| Speed range | rpm | 20 … 6,000 (… 7,500 / 10,000 / 12,500) |

| Motor spindle | . | |

| Tool holder | HSK-A 100 | |

| Drive power 25% c.d.f. | kW | 82 |

| Torque 25% c.d.f. | Nm | 237 |

| Speed range | rpm | 50 … 15,000 |

| Chain magazine | . | |

| Number of tool pockets | 40 (60 / 80 / 120) | |

| Max. tool diameter | mm | 325 |

| Max. tool length | mm | 800 |

| Max. tool weight | kg | 35 |

| Tower magazine | . | |

| Number of tool pockets | 180 (270 / 360 / 450) | |

| Max. tool diameter | mm | 340 |

| Max. tool length | mm | 450 / 800 (700 at MT) |

| Max. tool weight | kg | 35 (50) |

| Linear axes | X / Y / Z | |

| Position uncertainty P [Tp] | mm | ≤ 0.006 |

| Position scattering range Psmax | mm | ≤ 0.004 |

| NC rotary table / A-axis / B-axis | . | |

| Position uncertainty P [Tp] | sec | ≤ 6 |

| Position scattering range Psmax | sec | ≤ 4 |