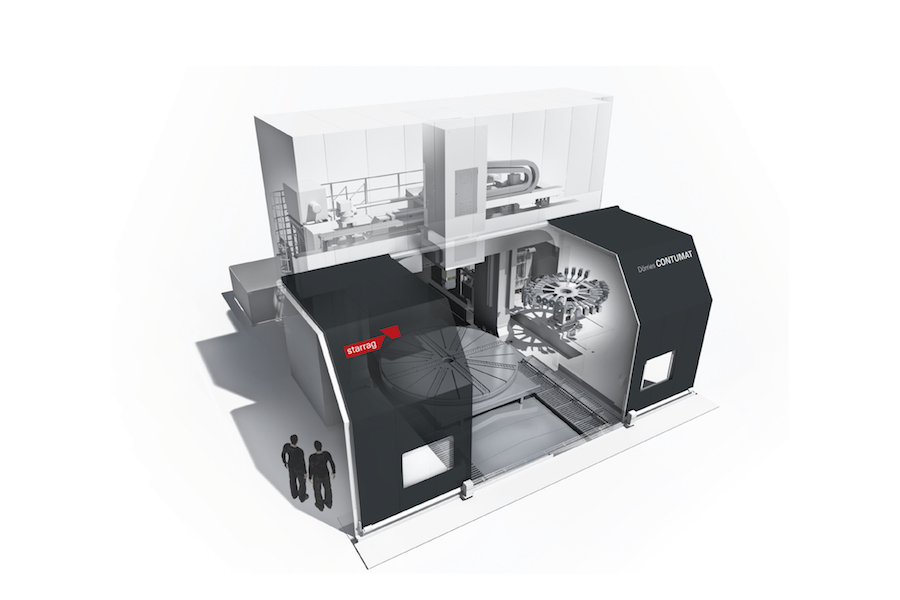

Dörries CONTUMAT VC 2000 V

vertical turning lathe

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VC-V provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VC-V machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VC-V machine range is capable of full 5 sided machining of components up to 472 inch in diameter and 771,617 lbs in weight.

On machines with a Y-axis the component can be machined in any position. The turning table is set on a sliding bed. The default Y-axis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Key benefits:

– Vibration damping cast construction

– High level of bending and torsion rigidity

– Rigid gantry design

– Linear travelling table (Y-axis)

– Hydrostatic flat guide rails

– Generously proportioned principal components

– High geometric precision

– Numerous machining table variants

– Flexible tool magazine variations

– High thermo-stability

– Comprehensive range of machining heads and accessories

– Machines tailored to customers requirements

Axis Configuration

Technical Data

Please choose the Measuring Unit

| Swing diameter | mm | 2,000 |

| Table diameter | mm | 1,600 / 1,800 |

| Y-axis | mm | +/- 1,000 |

| Working height max. | mm | 2,385 |

| Main drive S1 | kW | 2x 60 – 2x 150 |