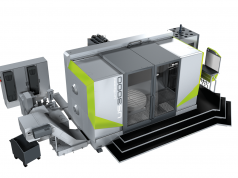

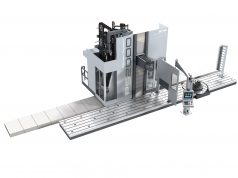

Heckert HEC 1600 Athletic

4-axis machining center

The flexible and modular-designed horizontal machining centers HEC 1000, HEC 1250, HEC 1600 und HEC 1800 Athletic ensure optimum results in the economic machining of workpieces with an edge length up to 1.900 mm, 2.400 mm, 3.000 mm, 3.300 mm and a maximum weight of 4.000 kg, 5.000 kg, 8.000 kg and 13.000 kg.

Due to complete and multi-sided machining in one clamping position, production and processing times are reduced, the machining quality is increased and the logistic costs are lowered.

The HEC 1000, HEC 1250, HEC 1600 and HEC 1800 Athletic offers a wide range of working spindle variants, process-optimized solutions for the tool and workpiece handling as well as innovative process control and monitoring systems.

The highly flexible modular principle ensures an individually customized solution for single-item, series or large-scale production. Fields of use of the monitoring machining centers are primarily the area of Transport & Industrial Components. The machining centers can be delivered as stand-alone machines, added with pallet storage system or integrated in flexible production systems for unattended production.

Key benefits:

– Customized version: Modular construction guarantees customizable manufacturing solutions

– Wide range of workspindles:

– Powerful horizontal spindles, modified in power and speed

– Horizontal/vertical milling heads for 5-side machining

– NC quills for low-lying form elements and long travels

– Reduction of manufacturing and floor-to-floor times: Assembly-ready complete machining in one clamping

– Machining quality to IT 5/6 and high long-term accuracy: Thermo-symmetrical machine design, FEM optimized main components, use of high-precision functional elements and high accuracy package as an option

– Reduction in setup times: Workpiece setup on separate loadunload station during processing

– Decrease in non-productive time: Highly dynamic tool handling and adjustment axes

– Savings on tool and operating costs: Modern process monitoring and high energy efficiency

Axis Configuration

Technical Data

Please choose the Measuring Unit

| Pallet clamping area | mm | 1,600 x 1,250 |

| Max. load | kg | 8,000 (13,000) |

| Max. speed | rpm | 8 |

| Workpiece swing diameter | mm | 2,800 (3,000) |

| Max. workpiece and clamping fixture height | mm | 2,200 |

| Linear travel X | mm | 2,800 |

| Vertical travel Y | mm | depending on support to 2,000 |

| Traverse travel Z | mm | 2,100 |

| Feed range, stepless | mm/min | 1 … 40,000 |

| Rapid traverse rate X / Y / Z | m/min | 40 |

| Feed force X / Y / Z | kN | 20 |

| H spindle | . | |

| Drive power 100% c.d.f. | kW | 29 |

| Drive power 25% c.d.f. | kW | 55 |

| Torque 100% c.d.f. | Nm | 936 |

| Torque 25% c.d.f. | Nm | 1,500 |

| Speed range, stepless | rpm | 20 … 6,000 |

| Tool taper | SK 50 (HSK-A 100) | |

| HV spindle | . | |

| Drive power 100% c.d.f. | kW | 29 |

| Drive power 60% c.d.f. | kW | 30 |

| Torque 100% c.d.f. | Nm | 985 |

| Torque 60% c.d.f. | Nm | 1,088 |

| Speed range, stepless | rpm | 20 … 6,000 |

| Tool taper | SK 50 (HSK-A 100) | |

| P 125 | . | |

| Quill diameter | mm | 125 |

| Drive power 100% c.d.f. | kW | 29 |

| Drive power 25% c.d.f. | kW | 55 |

| Torque 100% c.d.f. | Nm | 1,300 |

| Torque 25% c.d.f. | Nm | 2,470 |

| Speed range, stepless | rpm | 20 … 4,000 |

| Tool taper | SK 50 (HSK-A 100) | |

| P 150 | . | |

| Quill diameter | mm | 150 |

| Drive power 100% c.d.f. | kW | 41 |

| Drive power 40% c.d.f. | kW | 61,5 |

| Torque 100% c.d.f. | Nm | 1,500 |

| Torque 40% c.d.f. | Nm | 2,150 |

| Speed range, stepless | rpm | 20 … 5,000 |

| Tool taper | SK 50 (HSK-A 100) |

| Chain magazine | . | |

| Number of tool pockets | 40 (60 / 80 / 120) | |

| Max. tool diameter | mm | 325 |

| Max. T-type tool diameter | mm | 500 |

| Max. tool length | mm | 800 |

| Max. tool weight | kg | 35 |

| Tower magazine | . | |

| Number of tool pockets | 180 (270 / 360 / 450) | |

| Max. tool diameter | mm | 340 |

| Max. T-type tool diameter | mm | 950 |

| Max. tool length | mm | 450 (800) |

| Max. tool weight | kg | 35 (50) |

| Tool weight of all tools per tower | kg | 900 |

| Linear axes | X / Y / Z | |

| Positioning deviation P [Tp] | mm | ≤ 0.006 |

| Repeatability Psmax | mm | ≤ 0.004 |

| NC rotary table | B | |

| Positioning deviation P [Tp] | sec | ≤ 6 |

| Repeatability Psmax | sec | ≤ 4 |