CRASHGUARD

Real-time collision prevention

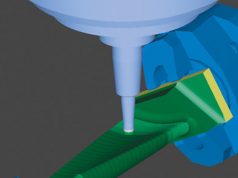

The patented CrashGuard collision prevention system is a real-time software extension of the CNC control system. Based on an internal 3D-model of the machine, it prevents collisions between machine components both in automatic and manual operation.

Thanks to a 3D collision forecast, which takes into account the acceleration limits of the NC-axes, CrashGuard therefore rules out collisions between the various machine components.

The users are free to define their own minimum safety distances between the various collision pairings, e.g. top slide – bottom slide.

CrashGuard permits only movements which have been tested for collisions, so that the uncertainty factor “reaction time” does not apply.

Software for real time collision prevention, integrated in the interpolator of the CNC system

For the machine operator

- Effective protection against collisions in automatic and manual operation

- Collision-free operation even after program interruptions and manual intervention

- At any time, the CNC system is aware of current positions of axes and speeds, PLC signals are also taken into account

- Current settings of the control such as zero offsets, coordinate transformation, etc. are taken into account

- „Reaction time“ = 0 !!! (breaking distances are taken into account in the NC interpolator in advance, so that the result is not just near real time, but real time!)

- All 3D geometry data (tools, clamping devices and workpieces) can be used for both CrashGuard and CrashGuard Studio. The two systems complement each other!