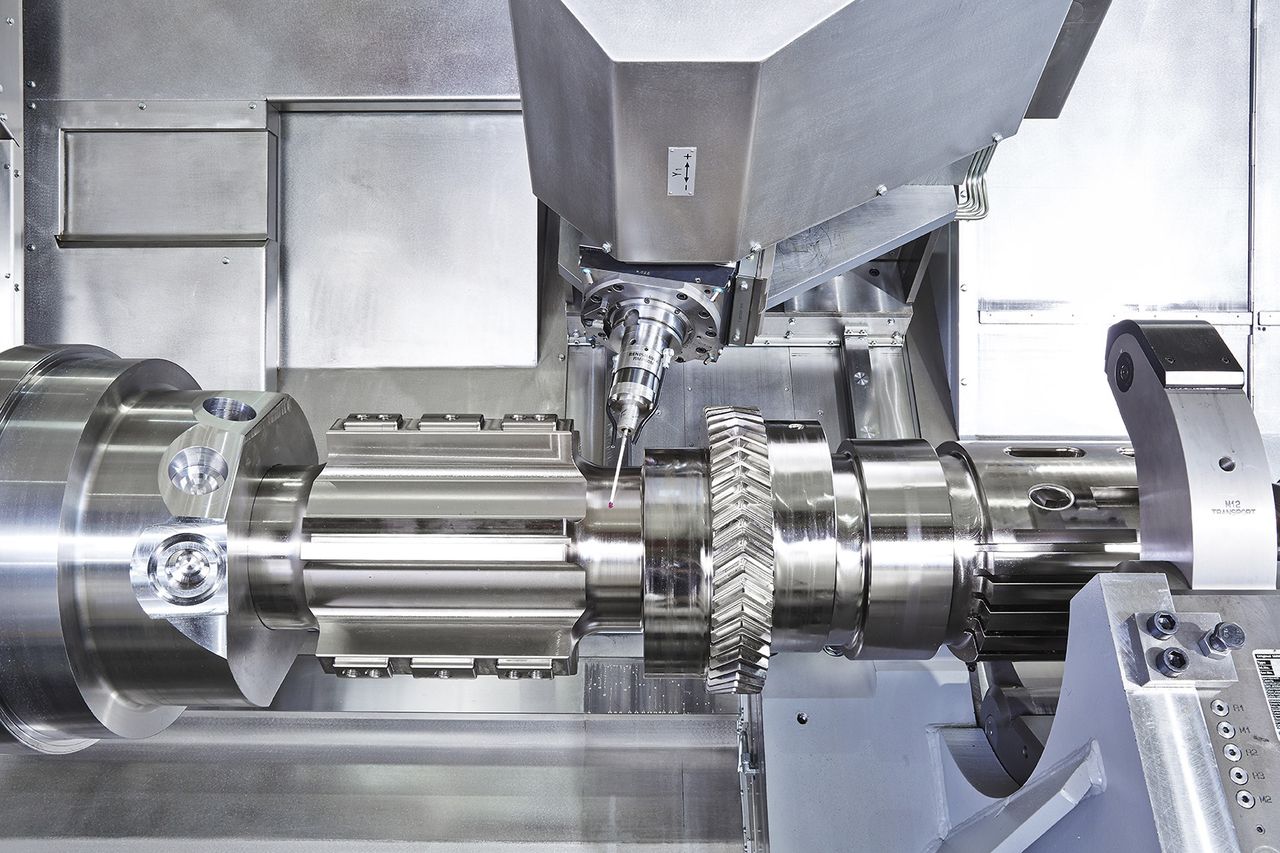

M65 Millturn

Combining all machining and measuring operations into a single MILLTURN complete machining centre from WFL massively increases the efficiency of your manufacturing. The unique MILLTURNTM machine concept and turning-boring-milling unit with gearbox guarantees unparalleled chipping performance with the highest level of precision. An investment that pays dividends very quickly.

Find the right MILLTURN for your application:

WFL currently has over 20 different MILLTURN models available: With turning lengths from 1000 to 14000 mm and turning diameters from 520 to 2000 mm, an extensive range of workpieces can be machined completely. Almost all MILLTURN models are also available as counter spindle variants (with the identification – G).

MILLTURNTM STANDS FOR:

- Wide range of machining technologies

- Highest level of productivity

- Highest stability and precision

- Highest flexibility in manufacturing

Technical data |

M65 |

|||

|---|---|---|---|---|

| Nominal center distancea | mm | 1000/2000 /3000/4500 |

||

| Swing – ø over Top slide | mm | 830 | ||

| Max. Turning- ø between centers | mm | 830(760) | ||

| Max. power, Turning spindle 100% duty cycle | kW | 40/60 | ||

| Max. torque, Turning spindle 100% duty cycle | Nm | 2318/2748 | ||

| Max. spindle speed, Turning spindle | min-1 | 2600/2600 | ||

| Max. power, Miling spindle 100% duty cycle | kW | 30 | ||

| Max. torque, Milling spindle 100% duty cycle | Nm | 315 | ||

| Max. spindle speed, Milling spindle | min-1 | 6000 | ||

| Swiveling angle B – axis | degree | -110…+90 | ||

| Travel Y – axis | mm | 600(-200…+400) | ||

| Travel Y – axis (option) | mm | – | ||

| Travel X – axis | mm | 720(-20…+700) | ||

| Tailstock | type | Mechatronic | ||

| Tool magazine | number | 40/80/120 | ||

| Control SIEMENS | type | SINUMERIK 840D sl |