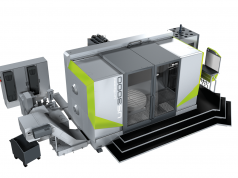

Heckert HEC 800 Athletic

4-axis machining center

The medium-sized all round machining centers guarantee maximum efficiency, high machining quality and reliability for the entire metal working industry. The modular design of the centers ensures maximum flexibility and allows optimised manufacturing solutions to be created. Customers can choose between three different working spindles, various tool magazines and a wide range of special designs and accessories.

Key benefits:

– High flexibility machining (choice of fixed or traversing horizontal spindle and pivoting horizontal/vertical milling head)

– Wide range of spindle powers (40 to 105 hp)

– Reduced down times (partly due to dynamic adjustment axes)

– Effective workpiece and tool handling

– High functional reliability due to gantry construction of the table group

– Multi-side and complete machining with high precision NC rotary table

– High rigidity of main assemblies (thermo-symmetry, compact construction)

– Dynamic and precise machining due to sophisticated drive technology

– Digital AC feed drives

– Sophisticated profile rail guides and circulating ball screw spindles in all linear axes

– Innovative tool management (chain or tower magazine with 120 or 320 pockets)

– Energy efficient machine concept with energy-saving functional elements

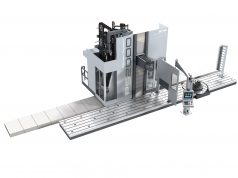

– Extension to create manufacturing cellsOptional expansion into flexible manufacturing systems with pallet storage

Axis Configuration

Technical Data

Please choose the Measuring Unit

| Clamping surface / perforated plate DIN 55201 | mm | 800 x 800 (1,000 x 800) |

| Max. load | kg | 2,000 (2,500) |

| Workpiece-interference diameter | mm | 1,400 (1,750) |

| Max. workpiece and clamping fixture height | mm | 1,400 |

| Rotation range B-axis | degree | 0 … 360 |

| Max. speed B-axis | rpm | 60 (500 at MT) |

| Number of changeable pallets | 2 |

| Linear travel X | mm | 1,450 |

| Vertical travel Y | mm | 1,100 (1,300) |

| Traverse travel Z | mm | 1,300 (2,050) |

| Max. feed range, stepless | mm/min | 1 … 65,000 |

| Rapid traverse rate | m/min | 65 |

| Max. acceleration X / Y / Z | m/s2 | 5 / 5 / 5 |

| Max. feed force X / Y / Z 60% c.d.f. | kN | 20 / 18 / 20 |

| H spindle | . | |

| Drive power 25% c.d.f. | kW | 55 (83 / 50 / 82) |

| Torque 25% c.d.f. | Nm | 1,500 (1,500 / 958 / 237) |

| Speed range | rpm | 20 … 6,000 (7,500 / 12,500 / 15,000) |

| Tool holder | HSK-A 100 (SK 50) | |

| HV spindle | . | |

| Drive power 60% c.d.f. | kW | 30 |

| Torque 60% c.d.f. | Nm | 1,088 |

| Speed range | rpm | 20 … 6,000 |

| Tool holder | HSK-A 100 (SK 50) | |

| P 125 | . | |

| Drive power 25% c.d.f. | kW | 55 |

| Torque 25% c.d.f. | Nm | 2,470 |

| Speed range | rpm | 20 … 4,000 |

| Quill stroke | mm | 500 |

| Quill diameter | mm | 125 |

| Tool holder | HSK-A 100 (SK 50) |

| Chain magazine | . | |

| Number of tool pockets | 40 (60 / 80 / 120) | |

| Max. tool diameter | mm | 325 |

| Max. tool length | mm | 800 |

| Max. tool weight | kg | 35 |

| Tower magazine | . | |

| Number of tool pockets | 180 (270 / 360 / 450) | |

| Max. tool diameter | mm | 340 |

| Max. tool length | mm | 450 (800) |

| Max. tool weight | kg | 35 (50) |

| Linear axes | X / Y / Z | |

| Position deviation P [Tp] | mm | ≤ 0.006 |

| Position scatter band Psmax | mm | ≤ 0.004 |

| NC rotary table / B-axis | . | |

| Position deviation P [Tp] | sec | ≤ 6 (≤ 4) |

| Position scatter band Psmax | sec | ≤ 4 (≤ 3) |